ProTransfers ™ (formerly DmandPrints)Outsource With ConfidenceProfessional DTF heat transfers trusted by shops, apparel brands, and creators who value consistent color, durable prints, and a partner they can rely on for outsourced production.

DmandPrints is Now ProTransfers ™

Same team, same service, same great transfers you’ve come to rely on—just a new name that better reflects our focus on professional-quality DTF heat transfers you can outsource with confidence.

Accurate Colors

We calibrate our entire printer fleet for ultra-precise color (that’s nerd speak for “basically perfect”)—so you and your customers get spot-on color every time.

Soft Natural Feel

Premium inks and adhesives, tuned with industrial printers and pro-grade software. Pressed at 280° for just 3 seconds—so your prints feel as good as they look.

Prints Arrive Pre-Cut

Every print arrives pre-cut at no extra cost—saving you time and keeping quality consistent for your customers.

Competitive Pricing

Volume discounts and special programs for qualified customers.

No Minimum Order

Order exactly what you need — no minimum quantities required

Rapid Turnaround

Receive your orers quickly with our efficient production and fast shipping services.

Heat Press Instructions

280° to 290°

DEGREES °F

Optimal DTF press temps are 280° to 290°F. This range creates a strong, soft bond without damaging your fabric.

3 - 5

SECONDS

Depending on your workflow and setup, a 3 to 5 second press time is ideal to ensure the best feel and color.

Recommended Workflow

Increase press time to 10–12 seconds if...

You are not following our recommended workflow and/or you

are not using a quality, accurate, and calibrated heat press.

Heat Press Instructions Demo

Time & Temp Comparison

The Science Behind Our Heat Press Instructions

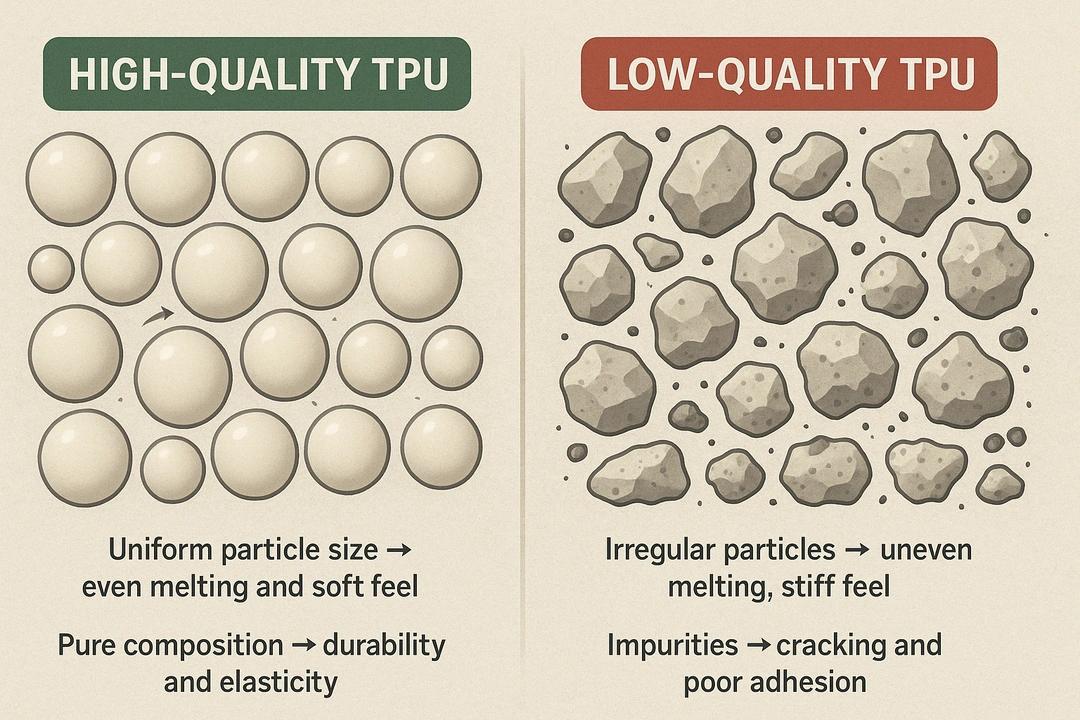

Not all DTF heat transfers are created equal.

DTF Color Masterclass

Important Direct To Film (DTF) Basics

DTF Color Basics

DTF Artwork Basics

Heat Pressing DTFs

Introducing Print Area™ Pricing Exclusively from Dmandprints

Say Goodbye to Gang Sheets

What People Are Saying

Essential Tips for Quality DTF Printing

What Makes Dmandprints Different

Popular Guides

Creating Images for DTFs

Feature Articles